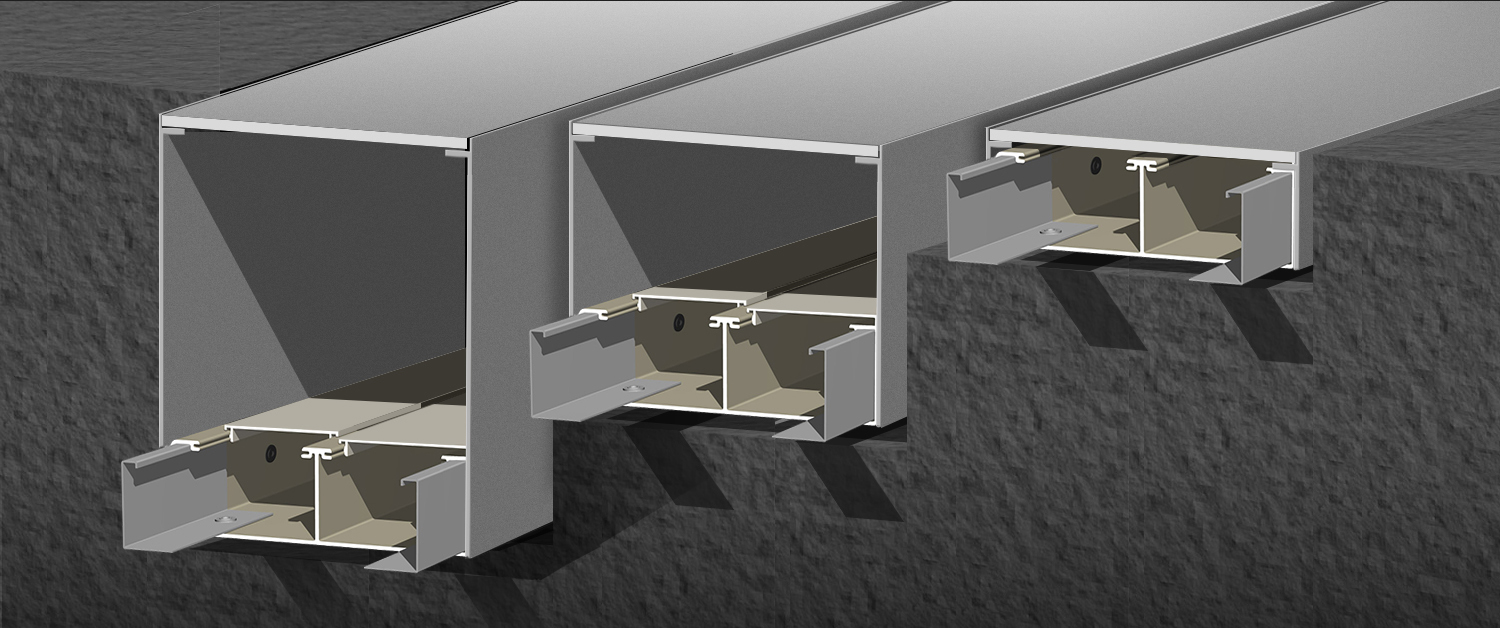

Floor trunking is usually fabricated to suit specific customer requirements. Interserv manufactures floor trunking from any profile. We choose from Cat 5 43mm deep through Cat 6 (60mm) and Cat 6A (100mm) up to Cat 7 which is 110mm deep, and one, two, three or more channels wide.

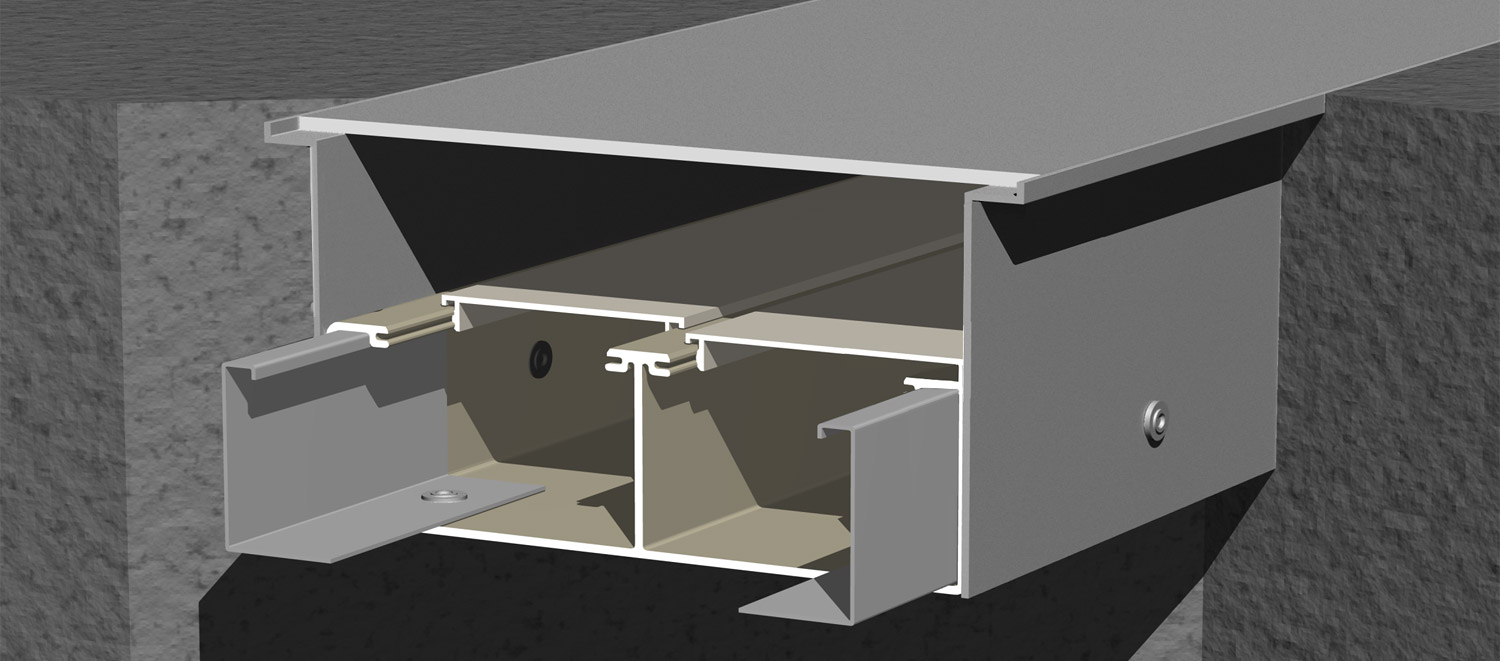

Interserv Floor trunking is EPC aluminium skirting with the floor trunk flanges riveted to the sides in shallow or deep configurations, plus a 4mm thick aluminium cover plate (can be suitable stainless steel) lying across the top between the purpose built side channels.

The flange channels act as side supports, give longitudinal and torsional rigidity until the setup is fully cured, and form the base into which CS stainless machine screws may be inserted through the cover to lock the cover in place. We use rivnuts if necessary to assist the installer achieving the perfect final level relative to FFL. The screws can be removed as the bedding compound sets, or not.

The cover plate is designed to sustain any amount of foot traffic, with and without access slots or hinged access plates, and if there was ever the slightest doubt of its carrying capacity in very wide installations support brackets can be added where needed along the length. The design is an integral whole, and a proven solution for accessible in-floor power and data reticulation. See selected profiles and examples shown below:

CAT 6 180/2 as example. We allow for Rivnuts installed into the base of the profiles. These provide for screw legs to assist setting the trunking height relative to the required FFL. The screws may be removed once the bedding compound has firmed sufficiently, or left in place as desired.

Floor trunking is usually fabricated to suit specifc customer requirements. lnterserv manufactures floor trunking from any profile. We choose from Cat 5 43mm deep through Cat 6 (60mm) and Cat 6A (100mm) up to Cat 7 which is 110mm deep, and one, two, three or more channels wide.

lnterserv Floor trunking is EPC aluminium skirting with the floor trunk flanges riveted to the sides in shallow, standard or deep configurations, plus a 6mm thick aluminium cover plate (can be suitable stainless steel) lying across the top between the purpose-built side channels.

The flange channels act as side supports, give longitudinal and torsional rigidity until the setup is fully cured, and form the base into which CS stainless machine screws may be inserted through the cover to lock the cover in place. We use rivnuts if necessary to assist the installer in achieving the perfect final level relative to FFL. These levelling screws may be removed as the bedding compound sets.

The cover plate is designed to sustain foot traffic, with and without access slots or hinged access plates. The design is an integral whole and a proven solution for accessible in-floor power and data reticulation. See selected profiles and examples shown below:

CAT 6 180/2 as an example. we allow for Rivnuts to be installed into the base of the profiles. these provide the screw legs to assist in setting the trunking to the required FFL. The screws may be removed once the bedding compound has firmed sufficiently, or left in place as desired.